Installation of a slewing ring: recommendations for reliable supports

The installation of a slewing ring is a key step in the design of rotating machines. To ensure the service life and reliability of your equipment, the choice and preparation of supports are essential. Discover our recommendations to avoid deformation and optimize performance.

Why is the rigidity of supports essential?

If the slewing ring is installed on a support that lacks rigidity, the stresses are not distributed evenly, which can lead to:

- Hard spots and blockages

- Premature wear of the track

- Reduced service life

Minimum thickness and structural reinforcements

The minimum thickness values are listed in our catalog.

Add reinforcement rings, aligned with the tread, for better load distribution.

Flatness tolerances and solutions

Flatness defects (short defects and long defects) can cause blockage areas. Please observe the tolerances specified in our catalog.

If you encounter difficulties, use epoxy resins to correct the surfaces.

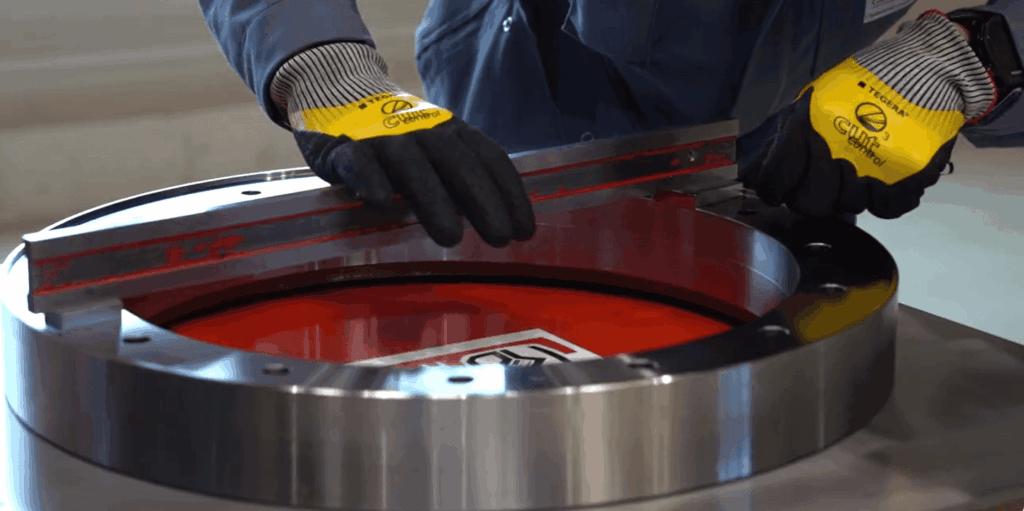

A well-designed support guarantees successful installation and optimal longevity. Follow the recommendations for rigidity, thickness, and tolerance to avoid mechanical problems. For more detailed information, please refer to our maintenance manual and the video tutorial on crown assembly and the importance of bracket flatness.