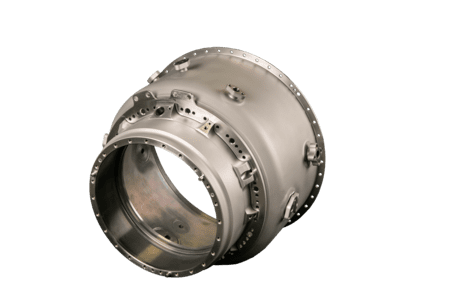

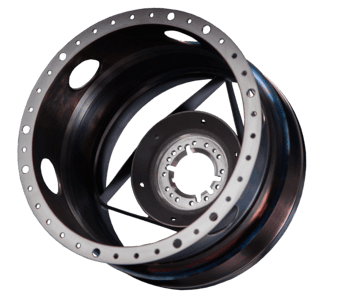

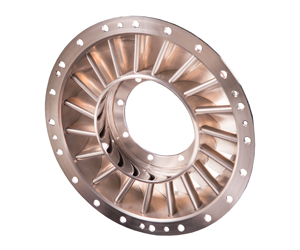

Defontaine remains a most valued partner for helicopter manufacturers, controlling the entire production process.

We ensure the supply and qualification of the raw materials we use. We work with various materials and alloys (titanium, aluminium, stainless steel, cobalt, nickel, etc.).

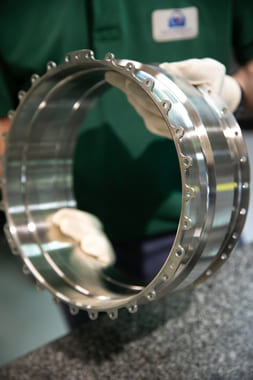

We process these materials independently on our production site, using specific forging, machining and assembly skills processes.

We master the supply chain for special processes, allowing us to offer turnkey solutions to our customers, and an exhaustive supply.

The organisation of our production workshops can meet the needs for reducing production cycles, from the development phase (FAST MAKE) to emergency management in AOG mode.