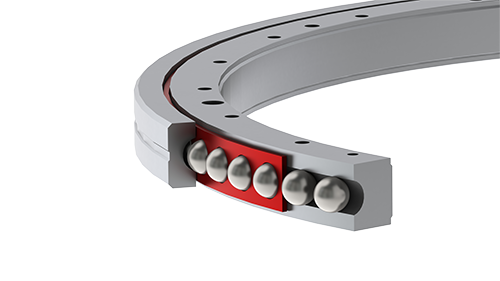

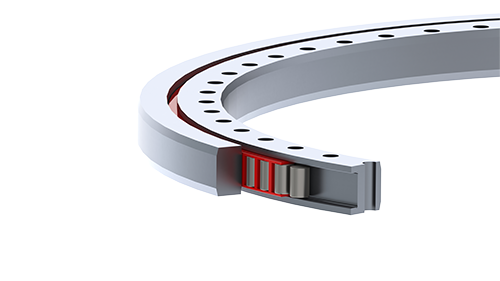

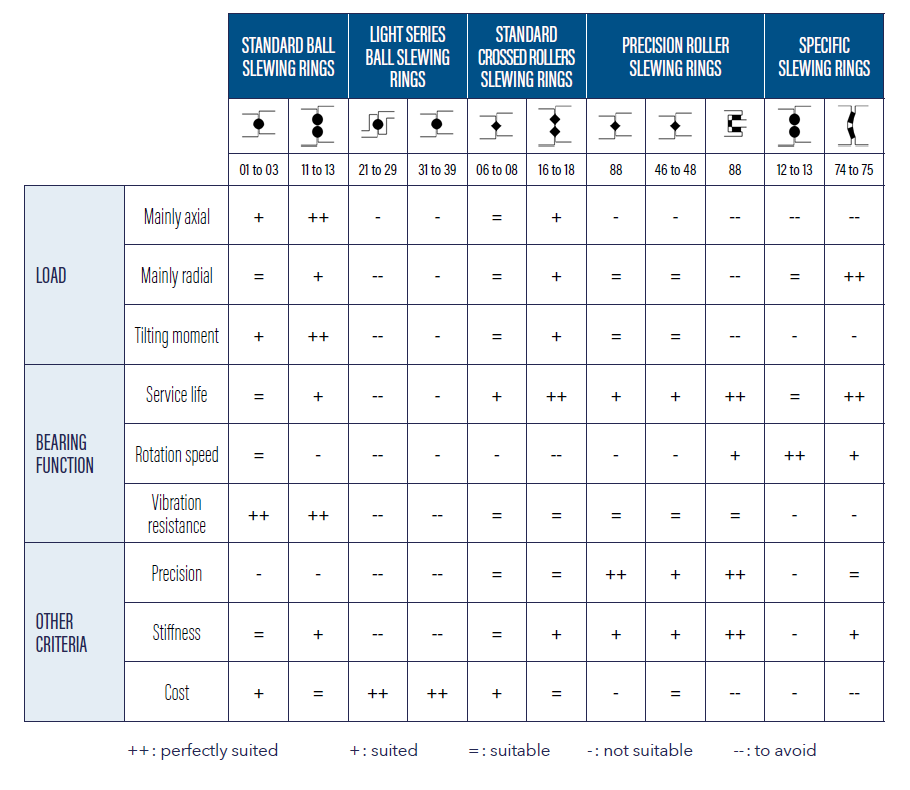

The quality and high precision of our products will ensure that your machines run smoothly and safely. Our range includes ball, cross roller bearing, and extends from standard slewing ring to customised rings according to your application requirements. Our design, research and development department, equipped with state-of-the-art test benches and calculation software, is at your service to offer innovative and adapted solutions.

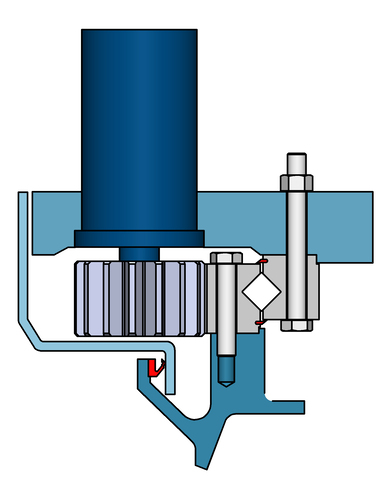

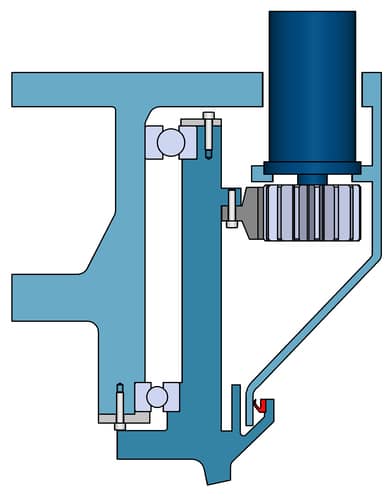

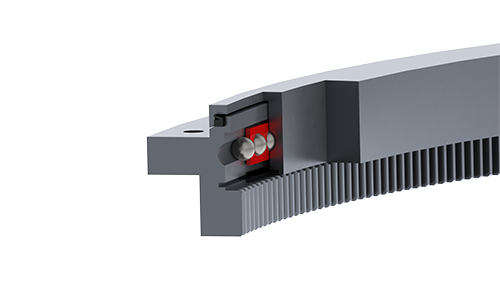

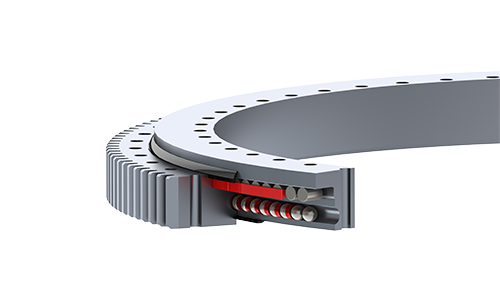

- Single or double row ball or roller bearings

- Slewing rings with external, internal, spur, helical gear or without gear

- Steel, titanium, aluminium, etc.

- Surface treatment and/or corrosion protection

- Standard or specific seals

- Lubricated-for-life rings, food-grade grease.

Flash-butt welding

Flash-butt welding Precision machining and grinding

Precision machining and grinding  Press quenching

Press quenching Induction heat treatment

Induction heat treatment  Special processes

Special processes