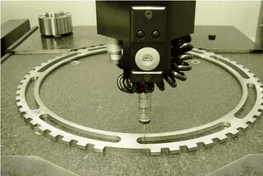

Defontaine designs and manufactures flywheels and starter ring gears using high-performance industrial equipment. Our production lines are automated and our distribution platforms are designed to ensure secure delivery and supply. This production tool, combined with skilled staff, guarantees high-quality production of starter ring gears and flywheels.

Our expertise allows us to provide for the complete supply of parts ready to be mounted on car engines as first-tier subcontractor for many of our customers.

Millions of starter rings and flywheels are produced in our factories every year to equip new vehicles. Our expertise is recognised by manufacturers and equipment suppliers throughout Europe.

Flash-butt welding

Flash-butt welding Precision machining and grinding

Precision machining and grinding  Press quenching

Press quenching Induction heat treatment

Induction heat treatment  Special processes

Special processes