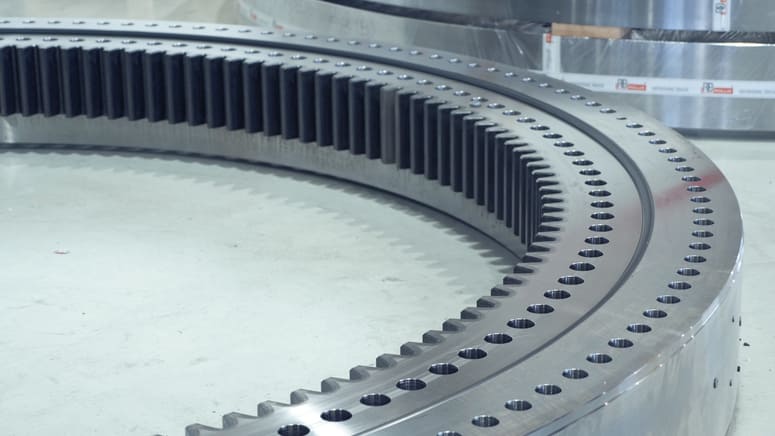

At Rollix, we have adapted and created a range of slewing rings designed to meet the constraints of the marine and offshore sector. Rollix’s engineering and R&D department offers products capable of withstanding marine constraints.

All Rollix parts are designed to withstand the marine environment with specific surface treatments and patented seals.