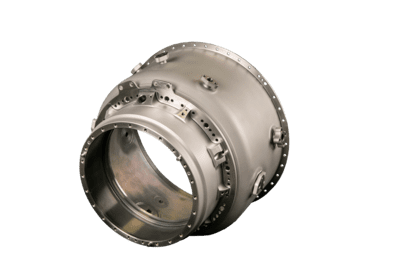

Defontaine provides specific expertise in the manufacture of casings for demanding applications. We master several manufacturing processes in order to produce machined or complex mechanical casings.

Defontaine uses foundry blanks or forged blanks supplied by our qualified partners to carry out high-precision machining and meet our customers’ requirements. Various special processes (thermal spraying, painting, anodising, etc.) and component assembly can complete the service offered by Defontaine, upon specific request.

Flash-butt welding

Flash-butt welding Precision machining and grinding

Precision machining and grinding Press quenching

Press quenching Induction heat treatment

Induction heat treatment Special processes

Special processes