Other sectors

Supporting all demanding industries in manufacturing of slewing rings, housings, flanges and other rings

- Home

- >

- Our markets

- >

- Other sectors

Defontaine Group, a renowned expert in various industrial sectors

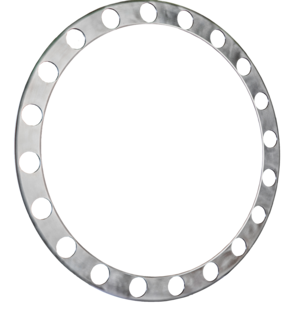

The Defontaine Group is one of the world’s leading manufacturers of slewing rings, housings, flanges and other rings. We export our production to more than 65 countries worldwide on all 5 continents.

The Defontaine group has the capacity to meet the needs of many sectors of activities: oil, gas, nuclear, construction, mining, handling, water treatment, etc. The group, with its Rollix and Defontaine brands, makes it possible to find solutions to meet specific demands in all sectors.

For each of our customers’ projects, we apply the rules of design for manufacturing, combined with a zero-defect policy. This process optimising method allows us to produce long-lasting quality parts.

We control the entire supply chain, from the supply of materials (steel, stainless steels, titanium alloys, aluminium, nickel and cobalt bases), to delivery to our customers’ sites worldwide.

We use special processes (welding, heat treatment, laboratory tests and non-destructive testing) certified by Nadcap and the most demanding manufacturers.

Certified production workshops:

- ISO 9001, 14001

- OHSAS 18001

- EN/AS 9100

- Nadcap Heat Treating, Nadcap Welding, Non destructive testing, Nadcap Material Testing Laboratory

Special applications

Slewing rings for special applications

Rollix has been designing and manufacturing slewing rings for specific applications such as radars, antennas and telescopes, in both civil and military applications, since 1977.

Our design office provides the expertise necessary to meet the most complex requirements for the manufacture of steel, aluminium or titanium rings. We use special materials withstanding extreme temperatures.

Rollix slewing rings for these applications are manufactured to combine accurate orientation, high-stiffness and very low torque.

Our products are designed in close cooperation with our customers to meet their particular specifications.

Construction

Slewing rings for the construction industry

Rollix has been supplying slewing rings for highly specific applications in the construction and public works sector since the 1970s. Our extensive expertise guarantees the delivery of preloaded rings combining reliability and performance, even in harsh environments.- Demolition robots

- Cranes: loader cranes, telescopic cranes

- Concrete pumps

- Drilling equipment

- Road machinery

- Dosing and mixing stations

Drone and aerospace

Other applications for our flanges and casings: drones and the aerospace industry

The Defontaine design office provides advice and designs custom-made casings, flanges or rings in collaboration with its customers.

We have the ability to apply new techniques and technologies to keep up with the developments in demanding industry sectors. Therefore, we can provide high-quality circular parts for your drones or for the aerospace industry.

Energy

Manufacturer of circular parts for gas turbines in the energy sector

Handling equipment

Slewing rings for handling equipment

Rollix supplies slewing rings for handling equipment. Rollix’s high-stiffness pre-stressed rings provide high-quality design perfectly fitted for the tallest telescopic lifts.- Gantry cranes on wheels

- Reach stackers

- Aerial platforms

- Fire trucks

Hydrogen

Flanges, rings or components for the hydrogen technology sector

Mining

Slewing rings for the mining

Rollix has been supplying large diameter slewing rings to leading customers in the mining industry for 40 years. For example, the 5-metre diameter slewing rings can be used to equip stacker-reclaimers. We provide a wide range of products from 150 mm to 6,000 mm for various complex applications in the mining sector from bucket excavators to ship loaders and unloaders. Our engineering expertise and production quality provide products- Stacker reclaimers / spreaders

- Bucket / chain excavators

- Ship loaders / unloaders

- Thickeners and clarifiers

- Multipurpose vehicles for underground mining.

Nuclear

Casings and flanges and other types of rings in the nuclear sector

- Flanges for valves,

- Flanges for waste containers,

- Slewing rings for handling equipment

Small wind turbines

Slewing rings for small wind turbines

Rollix is the leading supplier of blade rings and nacelles for the wind energy industry. 1 in 4 wind turbines is equipped with our rings, which represents 21% of the world’s existing wind farms.

At Rollix, we adapt and develop our range of rings for small wind turbines in close cooperation with the wind turbine manufacturers. We can produce slewing rings for small wind turbines from 10 kW upwards and without any limit.

Our wind turbine engineering department designs the rings based on finite element calculations. The slewing rings undergo extensive testing: on rolling elements, sealing, lubrication, thus allowing to produce extremely reliable parts.

Oil and Gas

Pipe reinforcement flanges for the oil and gas industry

Water treatment

Slewing rings for water treatment plants

Rollix has been supplying the world’s leading water treatment companies for over 40 years. The reliability of our parts guarantees the productivity of the stations.- Large clarifiers (scraper bridges)

- Suction hoses

- Thickeners (pickets)

- Suction bridges

Are you looking for a slewing ring in stock?

Would you like to know more about Defontaine casings?

Our associated services

Study

& design

Fast

Make

Logistics

Spares

& Services

Laboratory

We have set up specific services to guarantee the quality of our products and the satisfaction of our customers throughout our exchanges.

Deadline constraints, technical challenges, secure deliveries, guaranteed lifespan of parts… The services of the Defontaine Group facilitate our collaboration.