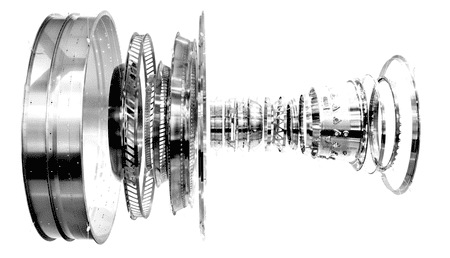

One of Defontaine’s greatest strengths: controlling every element of the production chain with the ability to offer an exhaustive supply.

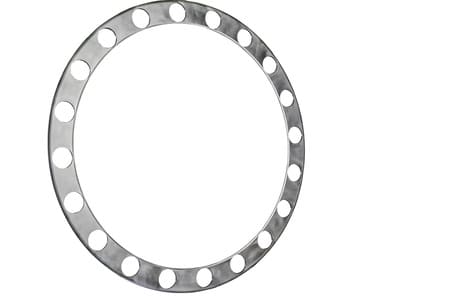

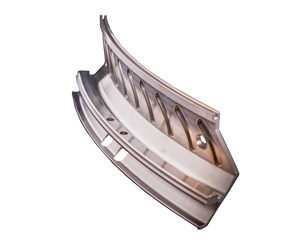

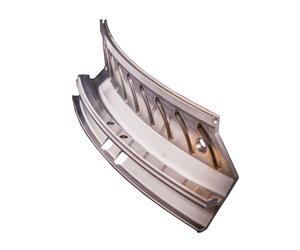

Supply of raw materials: we have the capacity to use a wide variety of materials. We work on cobalt, titanium, aluminium, stainless steel-based products, etc. and we have the skills required to process special alloys.

The application of specific processes (both forging and machining) and our zero defect principle guarantees 100% On Time Delivery.