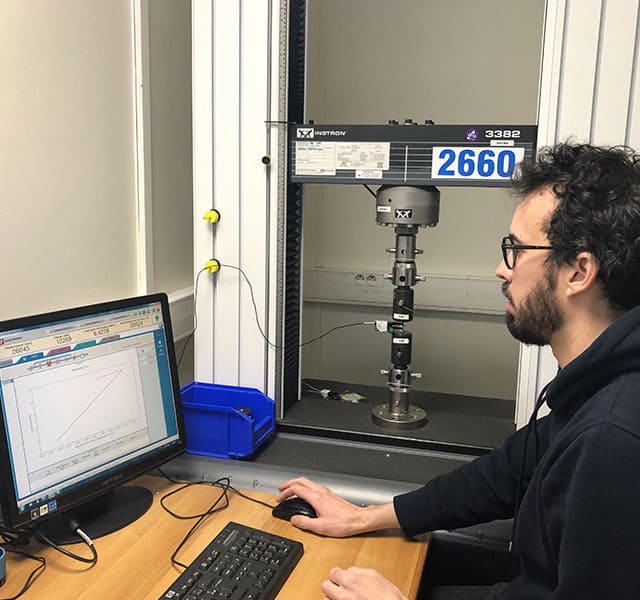

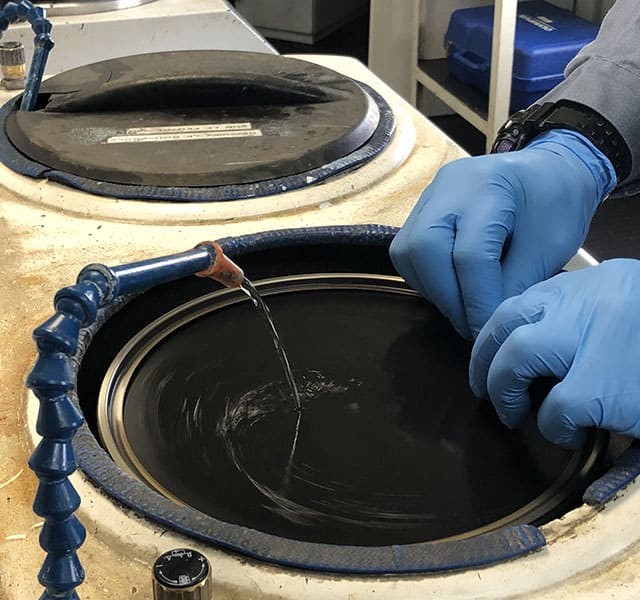

Defontaine materials testing laboratory, the key to cutting-edge innovation

The Defontaine Group team of highly qualified technicians is dedicated to innovation on a daily basis.

The materials testing laboratory is an essential structure to meet the demands of your applications and guarantee the quality, reliability and durability of our high precision parts.